The Right Release Agent

Game-changing release agents elevate the quality of your baked goods and enhance operational efficiency.

-

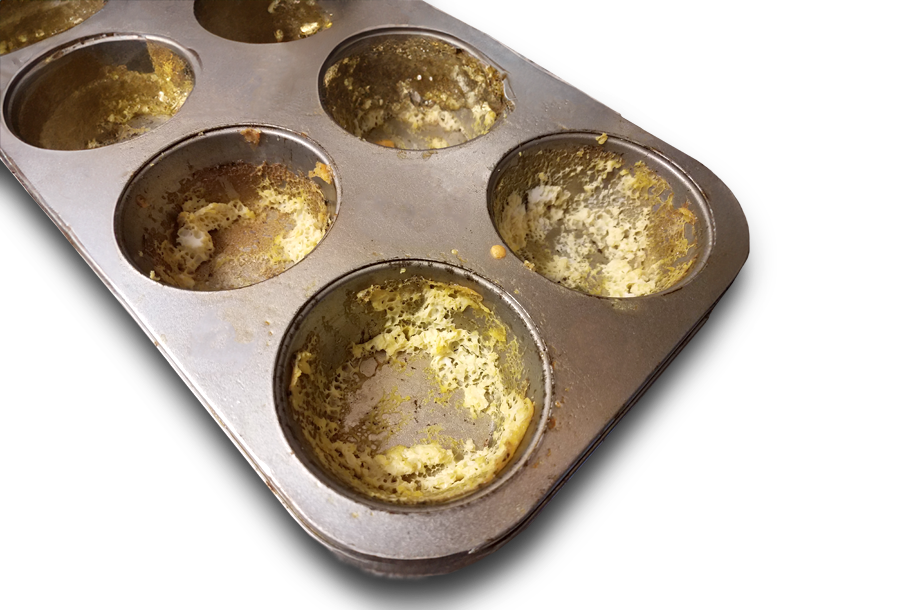

Flawless Release

Your creations will effortlessly detach from surfaces, minimizing waste and preserving product integrity.

-

Consistency is Key

Achieve uniformity with a release agent that promotes consistent texture, appearance and taste, leaving a lasting impression on your customers.

-

Operational Efficiency

Say goodbye to production slowdowns caused by sticking issues, improve your processes and streamline your production line.

-

Extended Equipment Life

Minimize adhesion and prevent buildup, maintain the longevity of your equipment and save on maintenance costs.

-

Tailored Solutions

Let us tailor a solution to align with the demands of your recipes and production methods.

Every sticky situation is an opportunity for improvement. Trust in our expertise and innovative solutions to not only address the challenges at hand but also to elevate the overall quality and efficiency of your baking operations.

Release Agents

The appropriate release agent can significantly enhance the quality of finished baked goods and help improve efficiency by:

- Preventing sudden line stoppages and product waste

- Reducing production costs

- Keeping conveyor belts as clean as possible

- Increasing equipment lifespan

There are two types of Release agents:

It's not how much release agent you use, it's how you apply the right release agent

Release Success Equals:

- Using the proper release agent for your application

- Good spay equipment, functioning properly

- Well-trained operations personnel

Custom Spray Equipment Solutions

Designed, built and serviced by in-house experts to support any food manufacturing operation, large or small

-

Effective Design

We design effectively for the environment and consider things like equipment mounting, access for maintenance and the amount of Overspray

-

Superior Construction, Control and Consistency

Our equipment performs the same over its lifetime

-

Smart Equipment

We've equipped with adaptive sensing and AI

-

Adjustability

Adjust equipment to match your desired spray patterns, volume control and nozzle cycle

-

Unmatched Technical Support and Service

We offer on-going technical field support